Magnesium alloy tube

Key words: magnesium alloy materials

Details

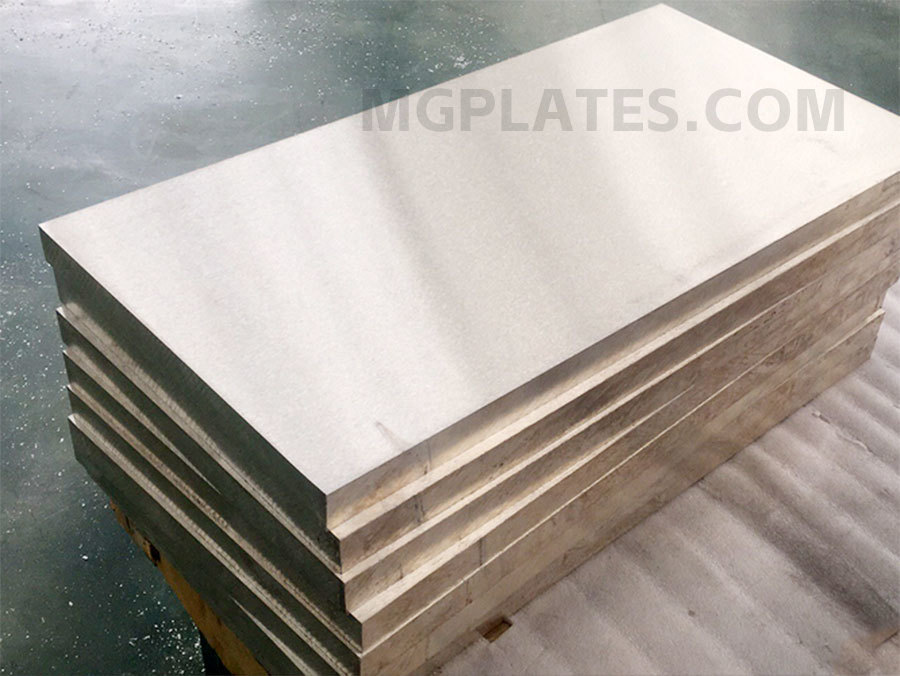

The magnesium alloy is a high-strength magnesium alloy containing zinc and zirconium, which is particularly important for its high tensile strength and good corrosion resistance. Magnesium alloys are often used in aerospace, automobile manufacturing, sports equipment and some engineering structures, especially those applications that require both high strength and light weight.

characteristics of magnesium alloy tube:

High strength and toughness: ZK60 alloy has high tensile strength and good impact resistance.

Good corrosion resistance: Compared with some other magnesium alloys, ZK60 alloy shows better corrosion resistance in some environments.

Machinability: Although magnesium alloys are generally inferior to some aluminum alloys, ZK60 alloys can be processed into complex shapes in various ways.

manufacture of magnesium alloy tube:

The magnesium alloy tube can be manufactured by processes such as extrusion and rolling. In order to improve the properties of the alloy, subsequent heat treatments, such as solution treatment and age hardening, may also be carried out to refine the grain structure and improve its strength.

Product Application:

Aerospace: Alloy tubes can be used for components of seat structures, wings and flaps of aircraft.

Automobile: The characteristics of high strength and light weight make it suitable for automobile wheels, cab structure and protective frame.

Sports equipment: such as bicycle frames, rock climbing equipment and golf club heads.

Manufacturing Standard:

Magnesium alloy pipe in the production and inspection, usually refer to the following standards:

ASTM B107/B107M: This is a universal standard for magnesium alloy extrusion products.

AMS 4352: This is a standard in the aerospace material specification (Aerospace Material Specifications) specifically for ZK60A-T5 extruded products.

Quality Control:

Magnesium alloy tubes also need strict quality control in the production process:

Chemical composition analysis: to ensure the accuracy and consistency of alloy composition.

Mechanical property test: such as tensile test, compression test, impact test, etc.

Non-destructive testing: such as X-ray or ultrasonic testing to ensure that there are no internal defects in the material.

Dimensional inspection: Ensure pipe size and shape meet customer specifications.

When purchasing magnesium alloy pipes, ensure that the supplier can provide suitable quality certificates and the products should meet the required industry standards and specifications. Due to the characteristics of magnesium alloys, they also require special care during storage and transportation to avoid humid and corrosive environments to maintain their performance and quality.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language