φ15mm magnesium alloy extruded bar

Key words: magnesium alloy materials

Details

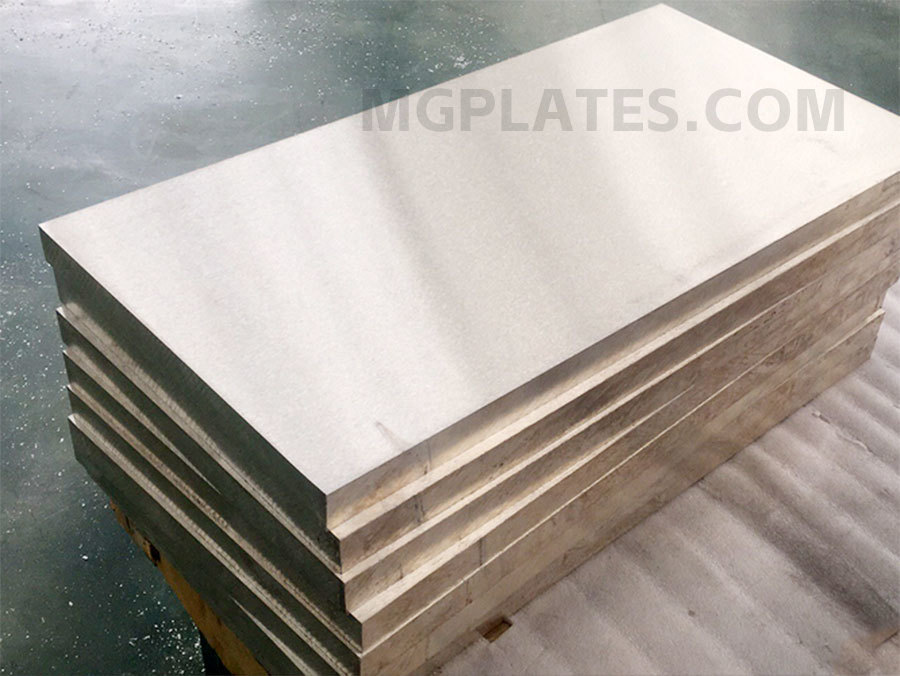

The φ15mm magnesium alloy extruded rod refers to a magnesium alloy material with a diameter of 15mm, which is produced by an extrusion process. Extrusion process is an efficient metal forming method, which is suitable for the production of long materials with consistent cross-section, such as bars and pipes.

Extrusion process:

1. Material preparation: heat the magnesium alloy billet to the extrusion temperature.

2. Extrusion forming: Put the heated magnesium alloy billet into the extruder and extrude it through the mold.

3. Cooling and cutting: After the extruded material is cooled, it is cut into a suitable length as required.

4. Heat treatment and surface treatment (if necessary): to improve the performance and appearance quality of the material.

Characteristics of φ15mm magnesium alloy extruded rod:

1. Light weight and high strength: Magnesium alloy is one of the very light industrial metals, and its strength can be improved by extrusion.

Good mechanical properties: extrusion can improve the yield strength and tensile strength of the material.

Excellent thermal conductivity: Magnesium alloys usually have good thermal conductivity.

4, corrosion resistance: through the appropriate alloy composition design and surface treatment, the extruded rod can show good corrosion resistance in a variety of environments.

Application areas:

Due to its characteristics, φ15mm magnesium alloy extrusion rod can be widely used in:

1. Automotive and aerospace: As structural parts and component materials, reduce weight and improve fuel efficiency.

2. Electronic products: used for radiator, casing and other components.

3, sports equipment: such as bicycle frame, mountaineering equipment, etc.

Machinery and automation: as raw materials for mechanical parts.

Standards and Codes:

The production of magnesium alloy extruded rods usually follows the relevant international and domestic standards, such as ASTM B107/B107M (standard specification magnesium alloy extruded rods, bars, wires, tubes and profiles), ISO standards, and China's GB standards. These standards specify the chemical composition, mechanical properties, dimensional tolerances and surface quality of the product.

Note:

1. Quality control: It is necessary to control the metal flow and temperature during the extrusion process to ensure the dimensional accuracy and microstructure of the product.

2. Post-treatment: Heat treatment and surface treatment may be required after extrusion to meet the requirements of specific applications.

3. Storage and handling: Due to the reactivity of magnesium alloys, moisture-proof and fire safety are required during storage and handling.

Depending on the requirements of the final application, magnesium alloy extruded rods may require further processing, such as precision machining, drilling, cutting, coating, etc. When selecting a φ15mm magnesium alloy extrusion rod, in addition to the size and shape of the foundation, the required alloy composition and the compatibility of subsequent processing should also be considered.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language