Application

The product application covers fields such as aerospace, military industry, rail transit, intelligent manufacturing, etc

high-speed rail

Development and Application of Magnesium Alloys

Now widely used magnesium alloy can be divided into two main types, one is cast magnesium alloy, the other is wrought magnesium alloy. At present, die casting magnesium alloy has been widely used in industry, magnesium alloy after deformation, can get more excellent comprehensive mechanical properties, so as to meet the needs of different occasions, so the development of wrought magnesium alloy is very promising.

The characteristics of magnesium alloy can meet the requirements of lightweight materials for noise reduction, vibration reduction and radiation protection in high-tech fields such as aerospace, and can greatly improve the aerodynamic performance of aircraft and significantly reduce the structural weight. At present, magnesium alloys are widely used in the aviation industry, including AZ91, AZ31, ZE41, QE22, WE43, etc.

Choose Quality

Lean management and improving product quality

Establishment time

Annual output

equipment

application

01

Production strength

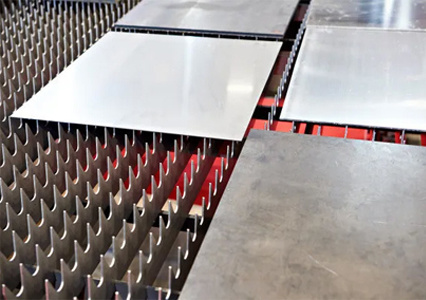

Advanced facilities enable us to produce high-quality magnesium alloy sheets using manufacturing processes

02

Quality Assurance

Strictly follow the ISO quality management system from raw material procurement to production processes

03

Deepening the team

Continuously deepening the system and 6S construction, striving to meet the constantly changing needs of customers

04

Quality Service

Provide comprehensive after-sales service. If you have any questions about the use of the product, please contact us in a timely manner

Quality inspection

Integrated professional services to ensure product quality

01

Appearance inspection

Firstly, the appearance of magnesium alloy die castings should be inspected to check for surface quality issues such as interference, surface bubbles, visible cracks, and paint peeling

02

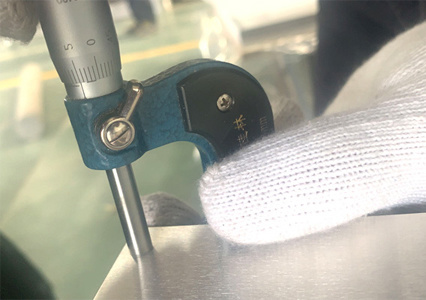

Dimensional inspection

Dimensional inspection involves various precision measuring tools and testing equipment, including calipers, inner diameter gauges, altimeters, and projectors

03

Physical Performance Testing

Physical performance testing is the testing of mechanical strength, bending strength, toughness, and plasticity of magnesium alloy die castings through experiments. Tensile test, hardness test, etc.

Related recommend

Establish a magnesium research center and technology center to develop products to meet different market demands

language

language