99.95 pure magnesium alloy pipe

Key words: magnesium alloy materials

Details

High-purity magnesium materials are generally used in special industrial applications, such as in aerospace, electronics and nuclear reactor technology. At this purity, magnesium contains almost no impurities of other elements, and is characterized by low resistivity, good thermal conductivity, and good shielding and vibration absorption properties.

application of high purity magnesium:

1. Sacrificial anode: used in seawater, sewage treatment system and pipeline protection to prevent metal corrosion.

2. Electronic and thermal conduction: The high electrical and thermal conductivity of high purity magnesium makes it suitable for heat dissipation components of electronic equipment.

3, electromagnetic shielding: in the need to shield electromagnetic interference equipment, you can use high purity magnesium.

4. Aerospace materials: Magnesium is used as a structural material in the aerospace field, and its high purity can provide better performance.

Nuclear industry: as a reactor material, because high purity magnesium has good neutron absorption ability.

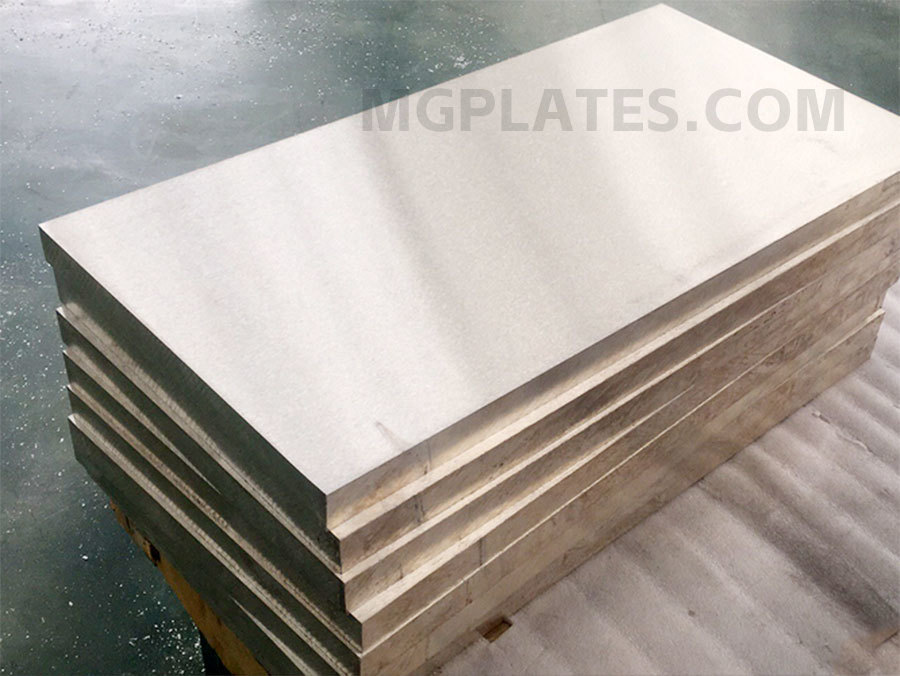

manufacture of high purity magnesium alloy tube:

The manufacture of 99.95 percent purity magnesium alloy tubes involves a complex refining and manufacturing process with the aim of significantly reducing the content of other elements. This may include:

1, electrolytic refining: through the electrolytic extraction of magnesium, can get very high purity.

Vacuum distillation: Distillation of magnesium at high temperature can further improve its purity.

3. Pollution control: Strictly control the environment during the manufacturing process to prevent impurities from mixing.

4. The production of high-purity magnesium pipes also needs to consider the processing and molding technology of materials, because magnesium metal has poor plasticity at room temperature and is prone to cracks. Therefore, the processing of high-purity magnesium pipes may need to be carried out in a protective atmosphere or after heating to a certain temperature to increase its plasticity.

Standards and specifications:

Due to the special use of high-purity magnesium, companies that produce such products usually customize the size and shape of magnesium tubes according to the needs of specific applications. In addition, manufacturers of high-purity magnesium may provide specific analytical evidence confirming the purity and performance of their material.

When ordering high-purity magnesium alloy tubes, the purity, mechanical properties, dimensional tolerances, and compliance with industry-specific quality standards should be clarified. Since these materials are usually custom products, it is recommended to communicate directly with the manufacturer to ensure that the product can meet specific technical requirements and application needs.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language