AZ31B magnesium alloy seamless tube

Key words: magnesium alloy materials

Details

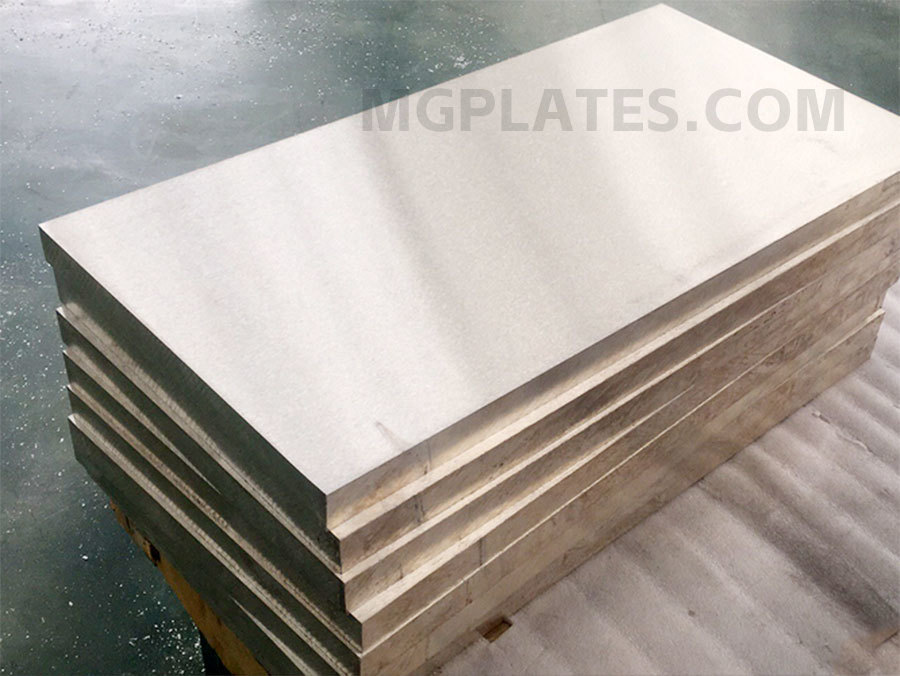

AZ31B magnesium alloy is a popular magnesium-based alloy, which is widely used for its good mechanical properties, high strength and toughness, and excellent corrosion resistance. This alloy contains aluminum (Al), zinc (Zn) and a small amount of manganese (Mn) as the main alloying elements, which together improve the strength and corrosion properties of the alloy. AZ31B alloy is often used to manufacture plates, bars, wires, and seamless tubes.

Manufacture of AZ31B Magnesium Alloy Seamless Tube

Manufacturing AZ31B magnesium alloy seamless tube usually uses the following several processes:

1. Extrusion process: the solid alloy is heated to a certain temperature to improve the plasticity, and then the seamless pipe is manufactured by extrusion molding. This method can produce pipes with accurate dimensions and smooth surfaces.

2. Spinning forming: on the rotating mold, the heated alloy plate is partially plastically deformed by the spinning tool.

3. Hot rolling or cold rolling process: continuous rolling at high temperature or room temperature through a rolling mill to directly manufacture tubular products from blanks.

Application of AZ31B Magnesium Alloy Seamless Pipe

AZ31B magnesium alloy seamless tube can be used in a variety of applications, including:

1. Aerospace field: such as the framework of aircraft seats, interior decoration, etc.

2. Automobile industry: used to produce automobile engine parts, transmission housings, cooling system parts, etc.

Bicycle manufacturing: Lightweight bicycle frames and components.

High-tech field: used to manufacture various high-precision instruments and equipment components.

Standard for AZ31B Magnesium Alloy Seamless Tube

Although the specific standards of international and domestic (such as China) may be different, magnesium alloy pipes usually need to comply with some basic quality standards and specifications, such:

ASTM B107/B107M: Standard Specification for Magnesium Alloy Extruded Bars, Bars, Wire, Tubes, and Shapes.

ASTM B91: Provides specifications for magnesium alloy forgings and extrusions.

Manufacturers may also have their own internal standards or follow customer-specific specifications to produce alloy tubes.

Quality Control

For AZ31B magnesium alloy seamless pipe, quality control is very critical, usually including:

1, chemical composition testing: to ensure that the alloy composition meets the specifications.

2. Mechanical performance test: test tensile strength, yield strength, elongation, etc.

3, size detection: to ensure that the product size is accurate, in line with the specified tolerance.

4, surface and microstructure inspection: to ensure that there are no surface defects, such as cracks, inclusions or non-metallic inclusions.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language