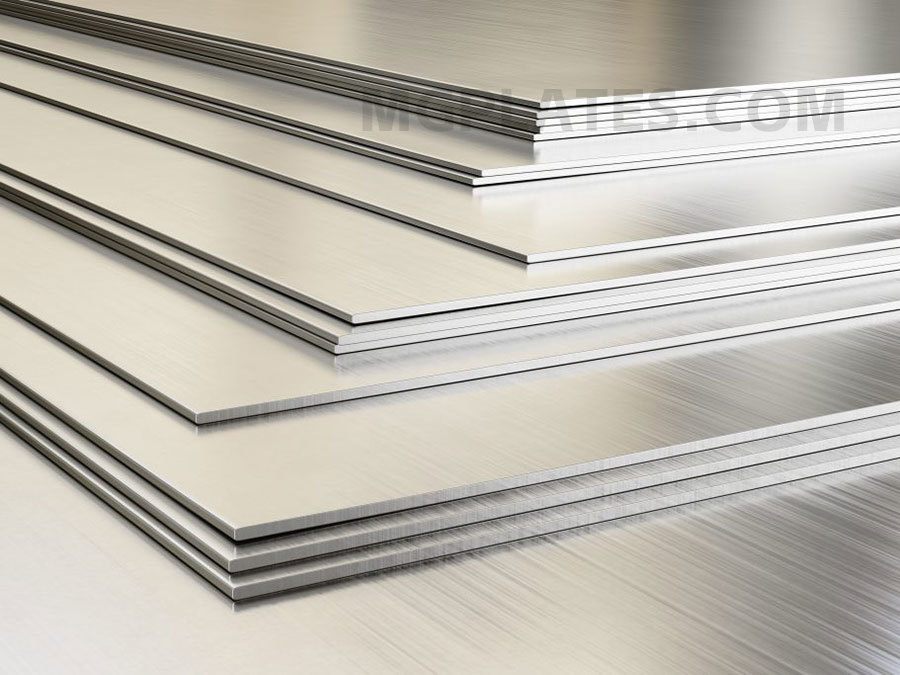

ZK60A magnesium alloy bar

Key words: magnesium alloy materials

Details

ZK60A is a commonly used magnesium alloy, mainly composed of magnesium, zinc and zirconium. This alloy is very popular in aerospace, automotive, defense and other high-performance applications because it provides good strength, toughness and corrosion resistance. ZK60A is usually used after heat treatment to improve its performance. The more common heat treatment states are T5 (artificial aging) and T6 (solution treatment and artificial aging).

ZK60A magnesium alloy characteristics:

1. High strength and hardness: ZK60A is a magnesium alloy with high strength and hardness.

Good corrosion resistance: Compared with other magnesium alloys, ZK60A has better corrosion resistance.

3. Excellent toughness: ZK60A is also favored for its good toughness, especially after heat treatment.

Easy to process: ZK60A is easy to machine before heat treatment.

Application:

The main applications of the ZK60A include but are not limited:

1. Aerospace: used for aircraft structural parts and flap systems.

2, automobile manufacturing: used to manufacture lightweight parts of automobiles.

3. Sports equipment: such as bicycle frames, tennis rackets, golf club heads, etc.

Military and Defense: As a structural material in some military equipment.

Standards and Codes:

In the production and supply of ZK60A magnesium alloy bars, it is necessary to follow specific national and international standards, such as ASTM, AMS (Aviation Material Standards) or other relevant military standards. These standards specify the chemical composition, mechanical properties, dimensional tolerances, surface quality and heat treatment conditions of the alloy.

Note:

1. Storage: Magnesium alloy bars should be stored in a dry, clean environment to avoid contact with corrosive substances.

2, safety: magnesium alloy processing should pay attention to safety, because they may burn at high temperature or fire source.

3. Heat treatment: The heat treatment of ZK60A should be carried out in strict accordance with the specified parameters to achieve the ideal material properties.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language