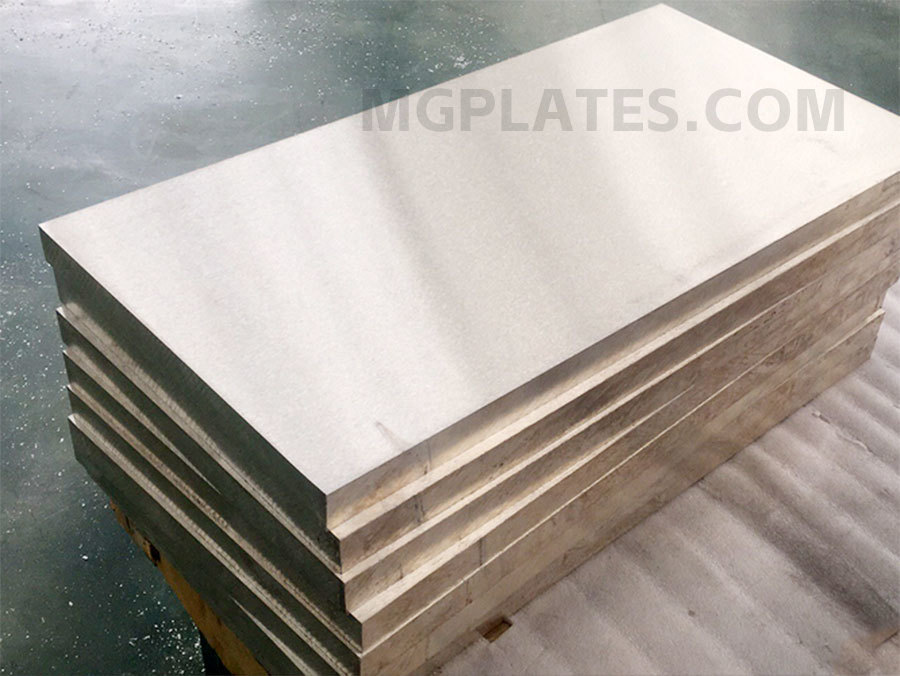

ZK61M Magnesium Alloy Extruded Rod

Key words: magnesium alloy materials

Details

ZK61M magnesium alloy is a kind of strengthened magnesium alloy, which mainly improves its performance by adding zinc (Zn) and zirconium (Zr). This alloy belongs to the magnesium-zinc-zirconium series, which is characterized by a trace addition of zirconium on the basis of zinc, which enhances its strength and hardness. ZK61M is usually used after heat treatment to achieve higher performance standards.

Features and Benefits:

1. High strength and hardness: ZK61M alloy provides much higher strength and hardness than pure magnesium.

2. Good corrosion resistance: The addition of zirconium improves the corrosion resistance of the alloy.

Good toughness: Even high-strength magnesium alloys can usually maintain good toughness.

4, heat treatment: through heat treatment, can further improve the mechanical properties of ZK61M.

5, suitable process: compared with other high-performance magnesium alloys, ZK61M alloy can also be formed by regular processing technology.

Application:

The application range of ZK61M magnesium alloy is similar to ZK60A. It is usually used in areas where high strength and good corrosion resistance are required, such:

1. Aerospace: as a structural material for aircraft, satellites or other aerospace vehicles.

Military industry: in armored vehicles, missiles and other defense systems.

3, sports equipment: manufacturing bicycles, mountaineering equipment, etc.

Automotive industry: production of lightweight components for high-performance vehicles.

Standards and Codes:

For the production and inspection of ZK61M magnesium alloy, there are also corresponding quality and industry standards, such as ASTM B107/B107M or corresponding AMS specifications. These standards typically include:

1, chemical composition: to ensure that the proportion of alloy elements in accordance with the provisions.

2. Mechanical properties: specify the strength, elongation and hardness of the alloy after heat treatment.

3, size and tolerance: clear product size requirements and allowable tolerances.

4, heat treatment conditions: specify the specific methods and parameters of heat treatment.

Note:

1. Safe operation: Magnesium alloys are easy to burn at high temperatures, so corresponding safety measures need to be taken during processing.

Heat treatment control: In order to ensure that the ZK61M alloy achieves the expected mechanical properties, the heat treatment process needs to be precisely controlled.

3. Anti-corrosion measures: Although the corrosion resistance of ZK61M is relatively good, additional surface treatment or protective measures may be required in certain environments.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language