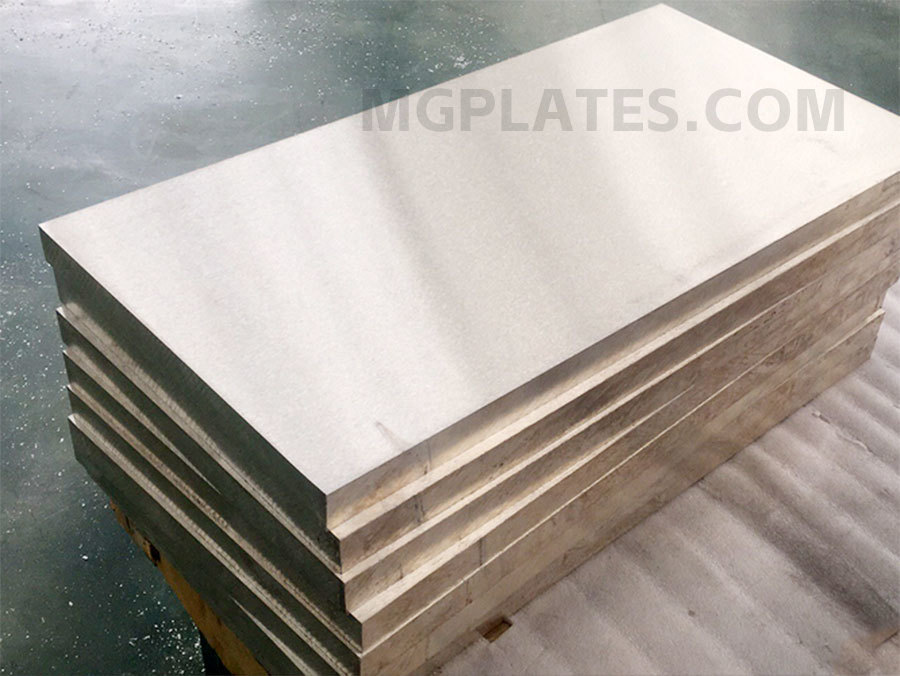

Magnesium alloy forged plate

Key words: magnesium alloy materials

Details

Magnesium alloy forging plate is a magnesium alloy product manufactured by forging process. Forging is a metal forming process that involves the use of pressure to mold a metal material into a desired shape and size. For magnesium alloys, forging can improve the mechanical properties of the material, such as improving strength, toughness and corrosion resistance, while reducing defects in the material.

Features of magnesium alloy forging plate:

High strength: The forging process can improve the yield strength and tensile strength of the material.

2. Excellent toughness: The forging process improves the toughness and fatigue strength of the material by refining the grains.

3. Improving microstructure: Forging helps to eliminate defects in as-cast materials, such as pores and inclusions.

4, custom shape: forging can produce parts close to the final shape, reducing the amount of machining.

Forging process:

Forging usually involves the following main steps:

Heating: First preheat the magnesium alloy to an appropriate temperature to facilitate forging.

2. Forging: Then put the heated metal in the forging die and apply pressure to deform it.

3, cutting and trimming: forged parts may need to remove excess flash edge, while the necessary machining.

Heat treatment: After the forging process, heat treatment may be required to further optimize the performance of the material.

Application areas:

Magnesium alloy wrought plates can be used in applications that require high-performance, lightweight materials, such:

1. Aerospace: aircraft structural parts, engine components, etc.

2. Automobile manufacturing: body parts, wheels, suspension systems, etc.

3. Sports equipment: high-performance bicycle frame, motorcycle parts, etc.

4. Industry: mechanical arm, precision instrument, etc.

Standards and Codes:

Wrought magnesium alloy products usually need to comply with a series of international and national standards, such as ASTM B91 (standard specification for wrought magnesium alloy products) and the corresponding national standards. These standards cover:

1. Chemical composition and mechanical properties of materials.

2. Tolerances, dimensions and surface quality of forged products.

3, different inspection and testing methods.

Note:

1, process control: forging process parameters such as temperature and pressure must be strictly controlled to ensure product quality.

2, heat treatment: heat treatment after forging is essential to achieve the ideal mechanical properties.

Corrosion protection: Although forging can improve corrosion resistance, additional surface treatment may be required in some applications.

Safety: When dealing with high-temperature metals, appropriate safety measures need to be taken, especially for flammable magnesium alloys.

Magnesium alloy forging plate is widely used in many industrial fields because of its high performance and light weight. Choosing the right forging process and subsequent treatment is the key to ensure that the product meets the application requirements.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language