Magnesium alloy casting plate

Key words: magnesium alloy materials

Details

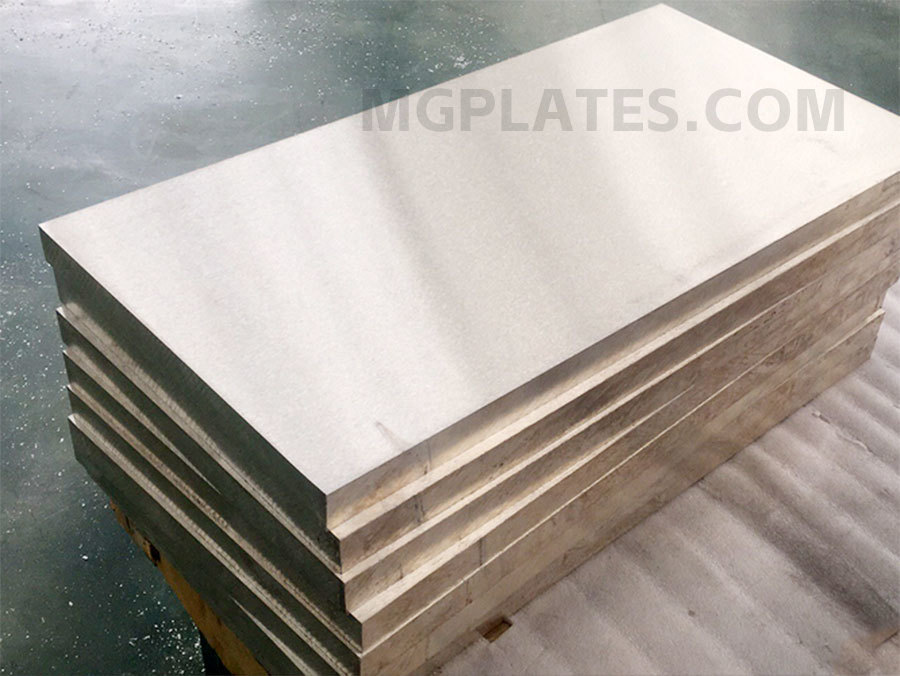

Magnesium alloy cast plate is made by casting process, and compared with the plate made by rolling or extrusion, the cast plate is usually used to make products with complex shape or high internal quality requirements. During the casting process, molten magnesium alloy is poured into a mold and solidified into a sheet of the desired shape. This process can be static casting, continuous casting and other forms.

characteristics of magnesium alloy casting plate:

Design flexibility: The casting process can produce parts with complex shapes, with less design restrictions.

2, internal quality control: through the appropriate process, you can get a more uniform and less defective internal structure.

Material cost: Casting can usually reduce the waste of materials, especially for parts with complex shapes.

4. Production efficiency: For small batch or customized products, casting may be a cost-effective option.

Casting process:

1. Smelting: The raw materials are melted into liquid magnesium alloy at high temperature.

Purification: Molten metal usually needs to be purified to remove impurities.

3. Casting: Pour the molten magnesium alloy into a pre-designed mold.

4, solidification: cooling and solidification in the mold to form castings.

5. Post-treatment: including removal of gate, riser, heat treatment, surface treatment, etc.

Application:

1. Aerospace: making spacecraft structural parts, engine parts, etc.

2. Automobile: manufacturing engine cover, wheel hub, etc.

3, communication equipment: used in the production of communication infrastructure components.

Medical devices: specific medical devices are made because of their biocompatibility.

Note:

1. Quality control: The casting process should be strictly controlled to prevent defects such as pores and inclusions.

2. Post-treatment: Cast plates usually require subsequent heat treatment to optimize their mechanical properties.

3. Corrosion protection: Surface treatment may be required to enhance corrosion resistance according to the application environment.

4. When casting magnesium alloy sheets, the performance requirements of the application should be fully considered to select the appropriate casting method and casting parameters. Due to the low ignition temperature of magnesium alloys, special attention should be paid to fire safety during the casting process.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language