Magnesium alloy casting rod

Key words: magnesium alloy materials

Details

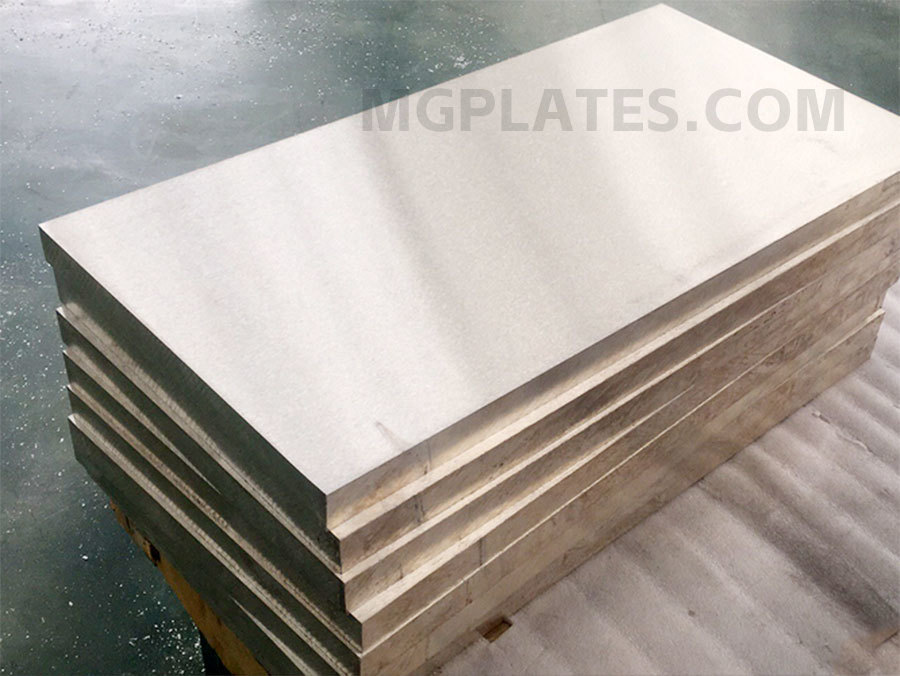

Magnesium alloy cast bars are made by a casting process, not by extrusion or rolling. In the casting process, molten magnesium alloy is poured into a prefabricated mold and cooled to solidify to form the desired shape. Casting is a common method for producing complex shapes and large-size magnesium alloy products. It can also be used to produce standard-sized round rods or other shaped materials.

Features:

High geometric freedom: casting can produce parts with complex shapes and many internal channels or cavities.

2. Mass production: suitable for medium to mass production, economical and effective.

Internal microstructure: castings usually have amorphous or coarse grain microstructure.

Material utilization: Casting can reduce material waste, especially for parts with complex shapes.

Application of casting rod:

Cast rods may be used in applications that require further processing, such as being cut or machined into specific parts. Casting rod materials are widely used in the automotive industry, aerospace, medical equipment, electronic equipment and other fields.

Standards and Codes:

The production of cast magnesium alloy rods generally follows the following international and regional standards:

ASTM B80: This is the American Society for Testing and Materials (ASTM) standard that specifies the technical requirements for magnesium alloy castings.

ISO 26202: Magnesium and magnesium alloys-International standard for technical conditions of casting.

Casting Technology:

Casting techniques include:

Sand casting: This is a traditional casting method that uses sand as the mold material.

2, die casting: high pressure die casting is a rapid casting process, suitable for high production of small to medium size complex parts.

3, precision casting: also known as investment casting or wax casting, suitable for the production of high precision and smooth surface parts.

Permanent mold casting: the use of metal molds to repeatedly produce castings of the same shape.

Note:

1. Casting defects: pores, shrinkage cavities, inclusions and cold shuts are common defects that may occur during the casting process.

2. Subsequent treatment: The cast bar may require heat treatment, surface treatment or machining to achieve the final required performance and dimensional accuracy.

Quality control: Non-destructive testing (such as X-ray or ultrasonic testing) is usually used to detect defects inside the casting.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language