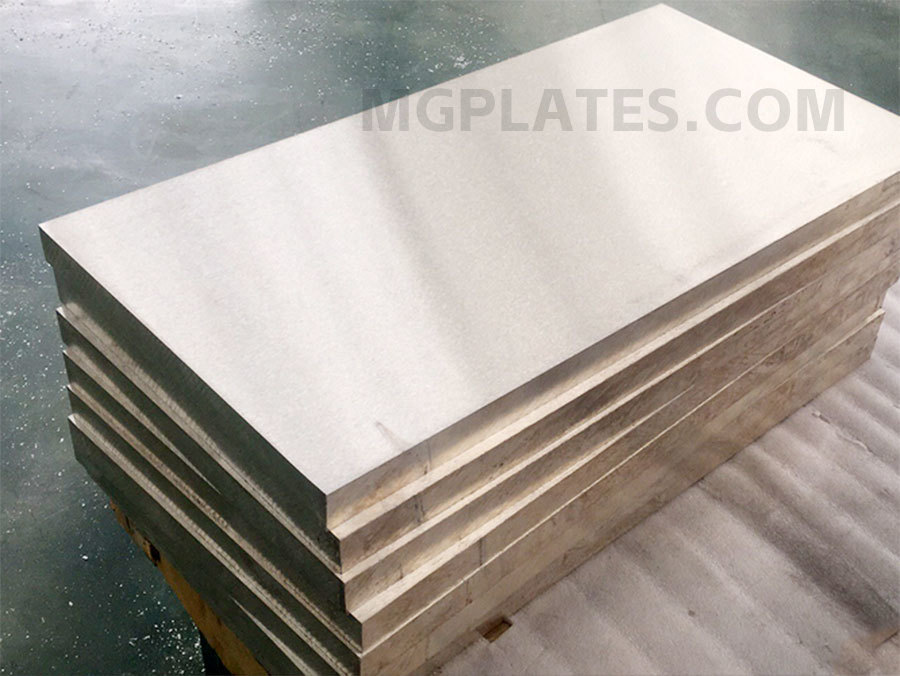

In stock CNC engraved magnesium board 600x914mm

Key words: magnesium alloy materials

Details

CNC engraving is a computer numerical control (CNC) way to engrave the material process, often used in metal, plastic, wood and other materials processing. The easy processing performance of magnesium alloy sheet just brings the gospel to the carving industry. It not only improves the engraving efficiency, but also has high reuse rate and saves cost.

For CNC engraving of magnesium plates (such as AZ31B magnesium alloy plates), the following is the process of CNC engraving:

1. Process selection

According to the thickness of the magnesium plate and the depth of the engraving, the appropriate tool and cutting parameters can be selected.

2. Tool selection

Choose a tool suitable for magnesium alloy materials, usually can choose carbide or other high hardness materials of the tool.

3. Parameter setting

Set the appropriate cutting speed, feed speed and cutting depth to prevent excessive wear of the workpiece and tool.

4. Lubrication and cooling

Magnesium alloys may generate high temperatures during cutting, and an appropriate amount of cutting fluid can be used for lubrication and cooling.

5. Safety measures

Since magnesium is an active metal, it is necessary to pay attention to the generation of sparks and heat during the cutting process to prevent fire risks.

6. Post-processing

After CNC engraving is completed, post-processing work such as deburring, polishing and surface treatment may be required.

7. Quality inspection

Quality inspection of finished engraved parts to ensure that the dimensional accuracy and surface quality meet the requirements.

8. Software Programming

Depending on the design of the engraving, the path can be programmed and simulated using CAD/CAM software.

Magnesium alloy engraving plate is a semi-continuous casting magnesium alloy ingot by 10,000-ton press extrusion, soaking furnace heat, leveling. It has a light specific gravity of magnesium alloy (the specific gravity of magnesium is 1.74g/cm3, only 2/3 of aluminum, 2/5 of titanium, 1/4 of steel and 1/5 of copper; Magnesium alloy is 36% lighter than aluminum alloy, 73% lighter than zinc alloy and 77% lighter than steel.) Good plasticity, very low thermal expansion and prestress, 30 times higher than aluminum damping performance, etc. Can be used repeatedly in the mold to save the mold, greatly improve the service life of the mold.

Magnesium alloy plate, as an excellent metal material that can be machined and engraved, has the following remarkable characteristics:

1. Magnesium alloy plate cutting inertia is small.

2. The magnesium alloy plate is stable in size after engraving and will not change with temperature fluctuations.

3. Engraving with magnesium alloy plate can significantly extend the life of the engraving tool, increase the engraving speed, and greatly reduce the engraving cost.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language