99.95% magnesium alloy bar

Key words: magnesium alloy materials

Details

Alloy bars containing 99.95 percent magnesium generally refer to high purity magnesium or nearly pure magnesium material. At this purity level, the material contains a very high amount of magnesium, while the content of other elements is very low. This material may be called high-purity magnesium rather than a magnesium alloy, because the term "alloy" usually refers to a material composed of two or more metal elements, and here, the proportion of other elements is very small.

Key features:

Low Density: Has a high specific strength (ratio of strength to weight).

Good mechanical properties: Although pure magnesium is not as strong as some magnesium alloys, it still has sufficient strength and ductility for some applications.

Excellent electromagnetic shielding: High purity magnesium is commonly used in electromagnetic shielding applications.

High thermal conductivity: Magnesium has very good thermal conductivity, suitable for radiators and heat exchangers.

Machinability: Magnesium and its alloys have good processing properties and can be processed into complex shapes by cutting, milling, and drilling.

Product use:

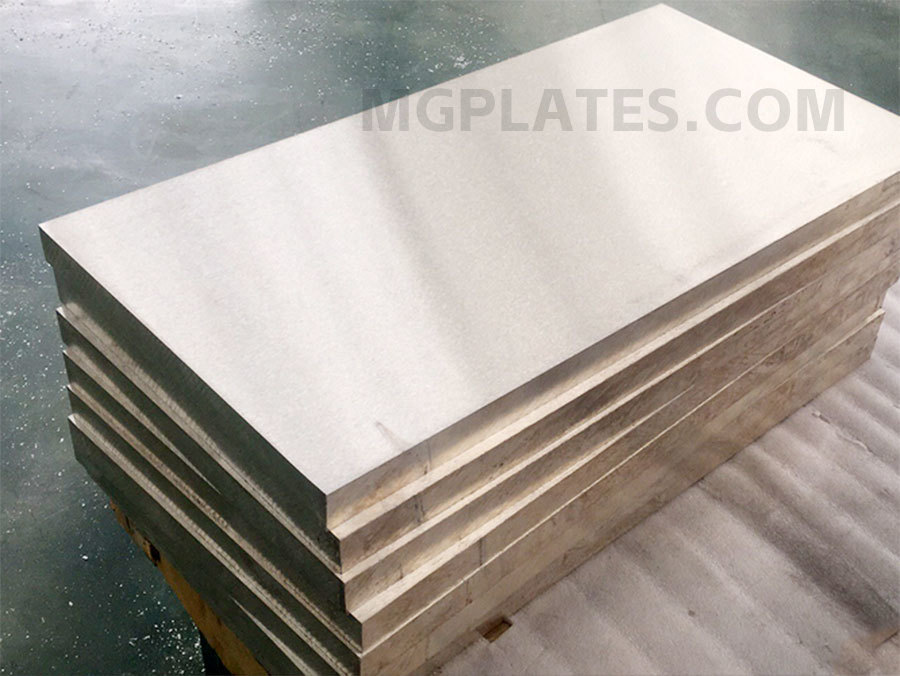

Sacrificial anode: as an anticorrosive sacrificial anode in seawater and soil.

Casting: Used as an additive for high-purity casting or to make casting models.

Battery: As an electrode material in some special types of batteries.

Research and development: for scientific research and the development of new materials.

Aerospace and military: In applications that require light weight and do not require extreme strength

Standards and Codes:

The production and inspection of high-purity magnesium rods usually requires a series of quality control standards to ensure that the material achieves the required purity and consistency. International standards that may be referenced include ASTM B92/B92M (Standard Specification for High Purity Magnesium Alloy Products). In addition, for specific applications, there may be more specific standards to specify the size, shape, surface quality and mechanical properties of the bar.

Note:

Storage and handling: High-purity magnesium can react with water to generate hydrogen under certain conditions, so it needs to be stored properly in a dry environment and pay attention to fire safety.

Corrosion protection: Although high-purity magnesium is relatively stable in dry environments, corrosion protection may be required in wet environments.

Impurity control: Impurities need to be strictly controlled during the manufacturing process to ensure that the material meets the purity requirement of 99.95%.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language