Magnesium alloy extruded rod

Key words: magnesium alloy materials

Details

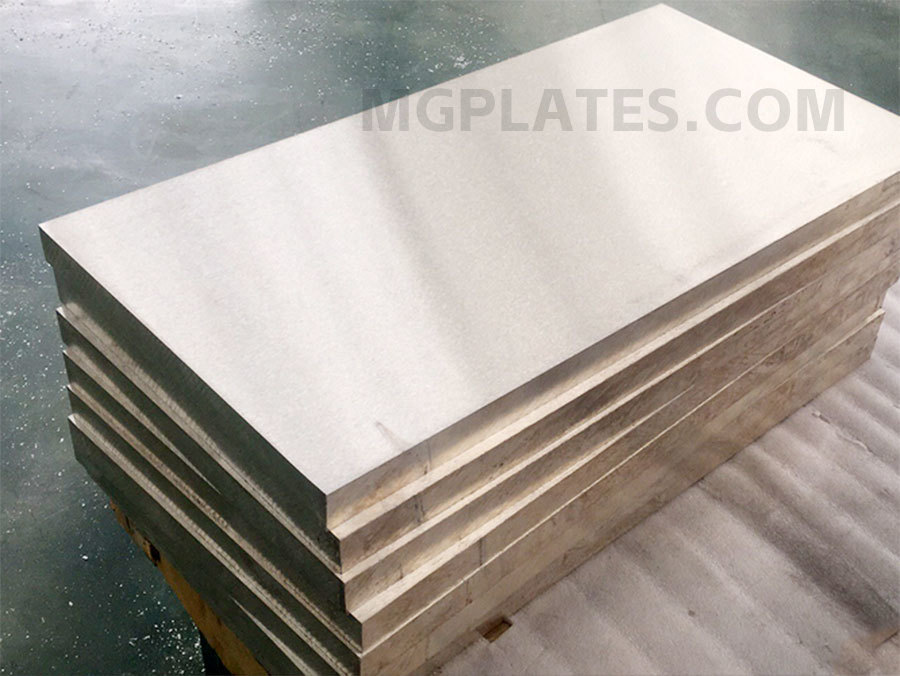

Magnesium alloy extruded rod is a kind of elongated material made by extrusion processing technology, which is mainly used in various engineering applications, including aviation, automobile, electronics, sports equipment and other industries. Extrusion is a hot working process that can produce magnesium alloy products with precise dimensions, complex cross-sections and excellent mechanical properties.

Extrusion process:

The extrusion process involves extruding a heated magnesium alloy billet through a die having a desired cross-sectional shape. This process can be carried out at high temperature, called hot extrusion, or at room temperature, called cold extrusion.

Product Features:

Lightweight: Magnesium is one of the extremely lightweight structural metals in the earth's crust, so the density of magnesium alloy extruded rods is very low.

High specific strength and specific stiffness: Compared with its mass, magnesium alloy has high strength and stiffness.

Good shock resistance: Magnesium alloy has a strong ability to absorb vibration and is suitable for shock absorption applications.

Good heat conduction performance: magnesium alloy can effectively dissipate heat, suitable for parts that need heat dissipation.

Recyclability: Magnesium alloy can be recycled, in line with the requirements of sustainable development.

Application areas:

Aerospace: Manufacture of aircraft seat frames, door frames, helicopter drive systems and other components.

Automobile industry: making automobile rims, seat frames, transmission system components, etc.

Electronic products: Magnesium alloys are used in notebook computer shells, camera frames, mobile phone shells, etc.

Sports equipment: such as bicycle frames, ski poles, golf club heads, etc.

Standards and Codes:

Magnesium alloy extruded rods are generally manufactured in accordance with international and national standards, such as ASTM, ISO, DIN, or country-specific standards. For example, ASTM B107 is a standard specification for magnesium alloy extruded rods, bars, profiles, and tubes.

Note:

Processing Note: Magnesium alloys are easy to burn during processing and must be carefully guarded against fire risks.

Corrosion protection: Although magnesium alloys have good corrosion resistance, in some environments, surface treatment may be required to improve corrosion resistance.

Storage and Handling: Magnesium alloys should be stored in a dry environment and handled carefully to prevent damage.

The exact specifications and performance indicators of magnesium alloy extruded rods usually depend on the specific composition of the alloy and the parameters of the extrusion process. Different alloy compositions (such as AZ31B, AZ61A, ZK60A, etc.) and different heat treatment states (such as T6, O, etc.) will lead to different mechanical properties and applicability. Therefore, the purchase should be based on the application needs to choose the appropriate magnesium alloy materials and specifications.

Application areas

electron

Car

printing

Needle plate

Aerospace

High-speed rail

recommend

after-sale service

One stop service system, pre-sales consultation, in sales service, after-sales support, and timely resolution of customer problems

Leave your message on the message board

language

language